The Future of Fashion & Sustainability | 23 De-Risking Fashion’s Supply Chain

The fashion industry’s environmental footprint is extensive, responsible for the accumulation of textile waste, water consumption and pollution, and greenhouse gas emissions. The industry contributes between 4-10% of global CO2e emissions through its complex global supply chain. The challenge lies in not only accurately measuring this impact but in addressing it across each step: from raw material sourcing to a garment’s disposal. Scope 3 emissions – those generated by suppliers and downstream activities like customer usage and disposal – account for 95% of apparel and textile retailers’ carbon footprint, yet these are the hardest to manage.[1]

While many brands historically treated supplier and manufacturing relationships as transactional, addressing Scope 3 emissions relies on close collaboration and investment.[2] Emerging manufacturing technologies can bridge this gap between suppliers and brands by delivering both economic and environmental benefits for all parties involved. Three companies – On Running, HILOS, and Unspun – are leading this transformation in textile manufacturing through advanced robotics, 3D printing, and automated weaving technology. While any substantial environmental and economic impact will depend on adoption, scale, and investment, these companies are reshaping how fashion products are designed, produced, and delivered to consumers.

On Running

On Running introduced the world to its CloudBoom Strike LS shoes ahead of the Summer 2024 Olympics. While the $330 price tag is sure to cause sticker shock, the highlight of this widely anticipated shoe is the innovation behind its single-piece upper. On Running worked with athletes over five years to construct a racing shoe with an upper that aims to give a “second-skin” feel by using their newly created and proprietary LightSpray™ technology.

LightSpray™ has robotic arms that contort and spin as the machine sprays 1.5km of white filament in a complex, pre-programmed pattern made to fit the mold’s specifications. The fiber fuses with the midsole to create an upper without relying on glues, seams, or laces. This one-step process cuts lead times by weeks, reduces material waste, and rids the need for several conventional manufacturing steps. The outsole is “computer-optimized” to be lightweight while retaining performance and constructed with a Double Helion™ HF hyper foam made to absorb impact. The result is a shoe weighing only 170g. In total, CloudBoom Strike LS shoes are made with just five parts, with the construction and coloring of the upper taking a total of 6 minutes.

LightSpray™ provides On Running with likely cost-savings but also helps bolster the brand’s sustainability ambitions. The production of CloudBoom Strike LS generates up to 75% lower carbon emissions compared to other On racing shoes.[3] According to a Life Cycle Assessment conducted by Vaayu – an environmental impact software – On Running achieves its carbon emission reduction potential due to more efficient use of raw materials, “cutting energy use, and reducing transportation emissions.[4] LightSpray™ technology…most significantly minimizes waste during production.”[5]

While the LightSpray™ technology was made specifically for the CloudBoom Strike LS running shoes, it would not be surprising to see On Running test their robotics and LightSpray™ technology with additional use cases. Early indicators signal the use of LightSpray™ as a significant improvement on existing processes. While footwear giants Nike and Adidas have debuted their share of footwear innovations since inception, LightSpray™ and the CloudBoom Strike LS is unlike any shoe these companies have produced. Naturally, with performance racing shoes, consumers care about durability and performance. Only time will tell how long the shoes may hold up, given the unique manufacturing and material construction, but consumers can expect the shoes to be made available to the public later this year.

HILOS

HILOS is revolutionizing footwear production and design with its integrated suite of design to 3D printing solutions. Their recently announced collaboration at the TechCrunch Disrupt conference with luxury footwear brand Steve Madden signals a potentially major shift in how shoes are made. HILOS’ value proposition? Produce footwear on-demand, with zero waste, integrating circular design, in as little as 72 hours.[6] HILOS’ approach seeks to answer a grave issue for the industry, footwear waste. According to shoe brand Vivobarefoot, of the 24 billion pairs of shoes produced each year, an estimated 22 billion end up in landfills.[7] 300 million pairs of shoes end up in landfills annually in the U.S. alone, while an estimated 70% of the material stock is wasted during product creation.[8] Steve Madden Chief Sustainability Officer Gregg Meyer is betting “We can produce faster, make less, but sell more.”[9]

HILOS takes a two-pronged approach: automate footwear design and upend manufacturing with a modular 3D-printing process. Earlier this year, HILOS introduced ManufacturingAI, an operating system (OS) for the footwear industry that integrates cloud-based design platforms like HILOS’ Interplay with 3D printing capabilities. Designers can generate, update, and improve their designs with text capabilities. One feature shown at TechCrunch Disrupt utilizes AR and AI systems to take sketches in real time and transform them into dynamic 3D models a designer can build upon to generate 3D printing files.

The magic happens when HILOS combines its software capabilities with its 3D printing process. HILOS uses powder-based printing, guaranteeing the highest quality and finish, so modular pieces have a “soft, suede, velvety feel.”[10] These pieces are then “easily and quickly assembled” with leather and knit materials for the resulting shoe.[11] The condensed shoe development process allows brands to design and produce low-quantity orders in as little as 72 hours. With limited quantities, brands can quickly test market demand for products and produce shoes on demand once orders are placed. The efficiencies in design and modular printing dramatically reduce the time it takes to go from concept to a launched product line, from years to weeks and months.

Beyond the manufacturing and technological advancements, HILOS’ production process helps brands avoid excess production and save energy resources. According to an environmental footprint assessment released in 2022 by Yale University, HILOS’ 3D manufacturing system “showed a 48% reduction in carbon and a 99% reduction in water usage compared to legacy manufacturing.”[12] However, the study does note, “Increasing energy efficiency in printing needs to be an ongoing focus…The energy required to recapture and recycle component parts can in some cases erode much of the benefits of displacing new virgin materials.”[13] The business opportunity is clear for brands, from the cost-savings to rapid market testing, but additional studies will be required to understand the environmental impact as the technology scales.

Unspun

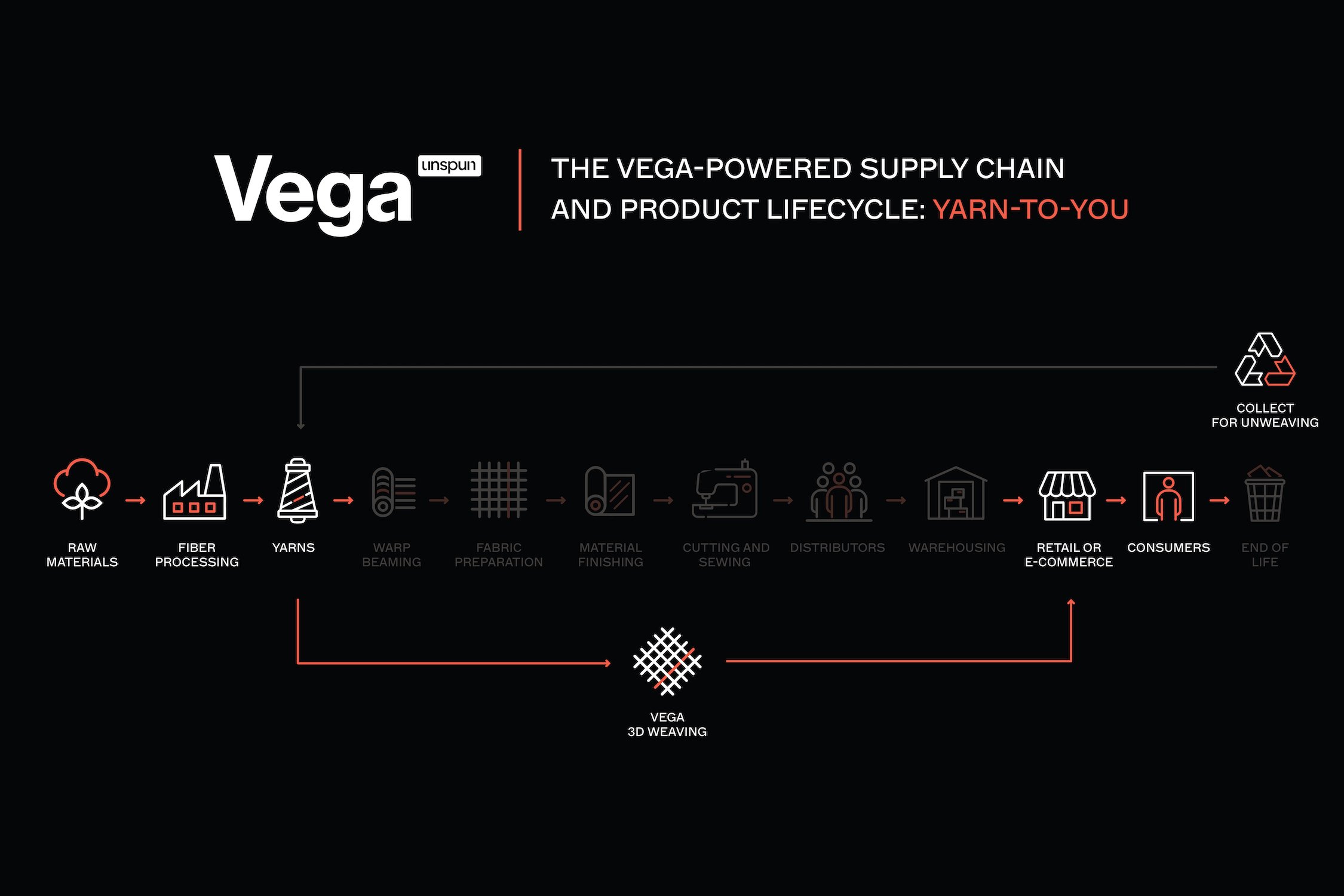

Manufacturing startup Unspun developed Vega™ 3D weaving technology to automate the supply chain for woven products with scalable on-demand and low-inventory production. While traditional methods of apparel production require fabric to be cut and stitched, Unspun’s 3D weaving technology skips these steps, going straight from yarn to garment. The company vertically integrates stages across the supply chain including fabric preparation, material finishing, and cutting & sewing into one process. The result is a more efficient system of production that minimizes waste and offers brands significant cost savings. Unspun even varies from other forms of 3D weaving by “building in a cylindrical base structure, [so] products can be completely or partially seamless, skipping many time-consuming and labor-intensive production stages.”[14]

[Source: Unspun]

Vega™ streamlines production processes to shorten the time it takes for raw materials to reach the customer. The result is an automated, low-impact production system. According to Unspun, Vega™ “accelerates production lead time from months to days.”[15] The increased speed and efficiency across the supply chain, lowers costs for brands and manufacturers, enabling them to produce goods locally in lower quantities by setting up “microfactories” with Vega™.[16] Brands can unlock a small batch, low-inventory or on-demand production cycle. Unlocking sustainable levels of production and minimizing overconsumption relies on technologies that can drive down the cost of manufacturing garments. These benefits are passed down to consumers in the form of greater quality control and design variations – without the impact of fast fashion.[17]

Brands and manufacturers can now license Vega™ machines to introduce 3D woven clothes into their product lines. Unspun is already partnering with brands across the U.S. and Europe. In March 2024, Unspun announced a partnership with Walmart “to explore manufacturing chinos in-house” using Vega™.[18] Meanwhile, Unspun has partnered with Europe’s largest sports retailer Decathlon to produce 3D woven clothes for several brands.[19] With their latest $32 million Series B funding round, Unspun will invest in building more Vega™ 3D weaving machines located in strategic manufacturing hubs and “operationalize 350 plus Vega™ machines across North America” by 2030.[20]

The future of fashion production won’t be built in massive factories halfway across the world. All three companies are showing that local, automated, and sustainable manufacturing is within reach – and profitable. The business case is compelling. Brands can accelerate production times and produce closer to their customers. Additional investment and adoption will be pivotal, but the solutions offer a compelling vision: clothing and footwear produced on-demand, with minimal waste, close to home. The cost of not doing anything is greater than the potential investment needed for scale and adoption.

On Running’s LightSpray™, HILOS’ integrated design and 3D printing, and Unspun’s Vega™ address fashion production’s biggest risks as climate change threatens to destabilize traditional manufacturing hubs. According to the Business of Fashion, extreme weather events “could jeopardise $65 billion worth of apparel exports and eliminate nearly one million jobs” by 2030 in Bangladesh, Cambodia, Pakistan, and Vietnam.[21] The resulting disruptions will ripple across the supply chain and ultimately hit brands’ bottom lines. Climate change is impacting the most crucial aspects of the supply chain. As these technologies scale, they promise to reshape the relationship with brands, manufacturers, and consumers. These innovations allow brands to embrace both profit and the planet.

[1] https://kohantextilejournal.com/fashion-industry-targets-climate-change-scope-emission-reductions/

[2] https://www.mckinsey.com/industries/retail/our-insights/apparel-brands-finally-shift-to-deeper-supplier-relationships

[3] https://www.on.com/en-us/lightspray

[4] LightSpray™ Life Cycle Assessment

[5] LightSpray™ Life Cycle Assessment

[6] https://hilos.studio/about

[7] https://www.vivobarefoot.com/media/wysiwyg/pdf/black_friday_revivo.pdf

[8] https://hilos.studio/about

[8] https://hilosphere.substack.com/p/unveiling-interplay-os-at-vogue-business

[9] https://footwearnews.com/business/technology/steve-madden-partners-hilos-on-demand-footwear-1234725452/

[10] https://techcrunch.com/2024/10/29/hilos-is-making-footwear-more-sustainable-without-skimping-on-style/

[11] https://techcrunch.com/2024/10/29/hilos-is-making-footwear-more-sustainable-without-skimping-on-style/

[12] https://footswearnews.com/business/technology/steve-madden-partners-hilos-on-demand-footwear-1234725452/

[13] https://www.newswire.com/news/hilos-releases-first-environmental-evaluation-of-3d-printed-footwear-21652275

[14] https://www.unspun.io/partnerships/decathlon?srsltid=AfmBOorWrdDMS1uHY92Ob0rvUt7Uh-Op7Nxg4KOrUAFrvcd8g4caw1dH

[15] https://www.newswire.com/news/hilos-releases-first-environmental-evaluation-of-3d-printed-footwear-21652275

[16] https://www.unspun.io/vega

[17] https://www.330trading.com/blogs/the-role-of-small-batch-production-in-the-future-of-apparel

[18] https://www.unspun.io/blog/post/disrupting-one-of-the-worlds-dirtiest-industries-unspuns-3d-weaving-loom

[19] https://www.unspun.io/partnerships/decathlon?srsltid=AfmBOorWrdDMS1uHY92Ob0rvUt7Uh-Op7Nxg4KOrUAFrvcd8g4caw1dH

[20] https://www.unspun.io/blog/post/bringing-vega-to-market

[21] https://www.businessoffashion.com/articles/sustainability/the-state-of-fashion-2024-report-climate-crisis-supply-chain-sustainability-environment/